washing machine The three-phase AC induction washing m […]

washing machine

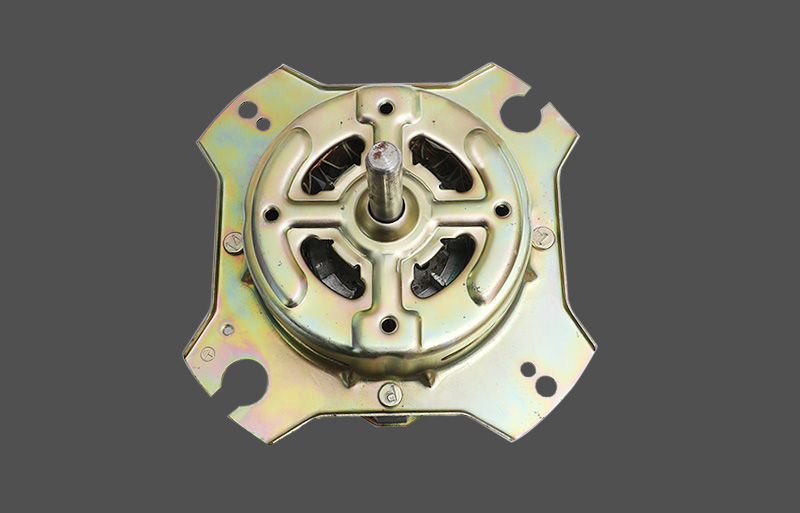

The three-phase AC induction washing machine drive responds to the new market demands for higher

performing appliances. The aim is to provide maximum drive performance at a competitive price, served

particularly well by Freescale Semiconductor's recently introduced 56F801x family of hybrid digital

signal processor/microcontroller (DSP/MCU) embedded controllers. An example drive design based on

the MC56F8013 offers the product designer plenty of computing power with advanced peripherals at a

very good price/performance ratio. The most important features of the drive include:? Three-phase AC induction motorMotor For Washing Machine Wholesalers

1Cost-efficient tachogenerator on motor shaft for speed sensing

2 Indirect vector control algorithm

3 Speed range 0 - 20000 RPM (motor speed), 0 - 2000 RPM (drum speed)

4Reconstruction of three-phase currents from DC-bus shunt resistor

5 Non-recuperative braking and deceleration control

6 Loss-minimizing control

7Over-current, over-voltage and under-voltage protection

8 Out-of-balance detection for spin dry

9 Serial RS232 control interface

It should be highlighted, the presented drive was developed with considerable unique requirements of the

washing machine application. The drive is designed to run a very wide range of speeds, from 0 - 20000

RPM. It is optimized to accept a wide range of loads. This feature reflects the condition of a real washer,

required to run reliably with both an empty drum and a drum fully stacked with wet and heavy clothes.

Another specific feature of the washer application is the ability to develop a high start-up torque for the

motor to force the full drum to move. As the efficiency of washing depends on precise speed control of the

washer drum, the presented drive comes with a PID speed control closed loop. Thanks to the inner closed

current control loop, the presented drive features high dynamics to achieve top performance control. It is

required to shorten the washing cycle as much as possible. A shortened washing cycle is achieved by using

a non-recuperative braking algorithm to stop the drum when it finishes a high speed spin-dry; a very

important aspect is energy efficiency. The presented drive comes with a loss-minimizing algorithm to run

at an optimum operating point and so save on valued energy. Thanks to selected control techniques, the

drive shows high immunity to motor parameter tolerances and to changes during its operation and

life-time.

Emphasis was put on the design of a product capable of competing in a market as cost sensitive as white

goods market require. Considering cost effectiveness, the drive reduces the number of current sensors. The

number of current sensors for sensing the motor current is reduced from three to a single-shunt resistor on

the DC-Bus. The three-phase motor currents are reconstructed from the DC-Bus current using an advanced

reconstruction technique.

Please leave your Email or phone nomber, so we can contact you as soon as possible.