In low temperature environments, the performance and reliability of the ventilator motor may be significantly affected, which is directly related to the operating efficiency and stability of the entire ventilation system. In order to ensure the normal operation of the ventilator motor under low temperature conditions, the following is a detailed introduction to targeted countermeasures.

Preheating and insulation measures

Motor preheating

It is important to implement preheating measures before activating the ventilator motor in cold environments. Preheating can be done in a variety of ways, such as using a resistance heater, a heat gun or a dedicated preheating device to heat the motor. The main goal of preheating is to increase the internal temperature of the motor, thereby reducing the viscosity of the lubricant and reducing friction between bearings and mechanical components. This not only helps the motor start smoothly, but also effectively reduces the inrush current at the start moment and reduces damage to the motor.

Application of thermal insulation materials

In order to ensure the stable operation of the motor in a low-temperature environment, it is necessary to wrap the motor with efficient insulation materials. Thermal insulation materials can significantly reduce the heat exchange between the motor and the external environment, thereby maintaining the stability of the internal temperature of the motor. Commonly used insulation materials include fiberglass, rock wool, polyurethane foam, etc. These materials not only have excellent insulation properties, but also have good fire protection properties.

Optimization of lubricants and lubrication systems

Choose low temperature lubricant

Under low temperature conditions, the properties of the lubricant inside the motor may change, become viscous or even solidify, resulting in reduced lubrication effect and increased wear of mechanical parts. Therefore, it is particularly important to choose lubricants suitable for low-temperature environments. Low-temperature lubricants can maintain good fluidity at low temperatures, ensuring smooth operation among the various components inside the motor, thereby improving the overall efficiency and life of the motor.

Lubrication system maintenance

Regular maintenance and inspection of the lubrication system is a key link to ensure stable operation of the motor in low temperature environments. It is necessary to regularly check the quality and quantity of lubricants, replace aged lubricants in a timely manner, and clean impurities and dirt in the lubrication system to ensure the normal operation of the lubrication system. Through these measures, failures caused by poor lubrication can be effectively prevented.

Motor parameter adjustment and optimization

Adjust motor starting parameters

In low temperature environments, the motor's starting parameters may need to be adjusted appropriately. For example, the duration or amplitude of the starting current can be increased to overcome starting difficulties caused by lubricant viscosity and increased friction of mechanical components. In addition, the operating parameters of the motor, such as speed and power, can be adjusted according to the operating requirements of the low-temperature environment to ensure the efficient operation of the motor under low-temperature conditions.

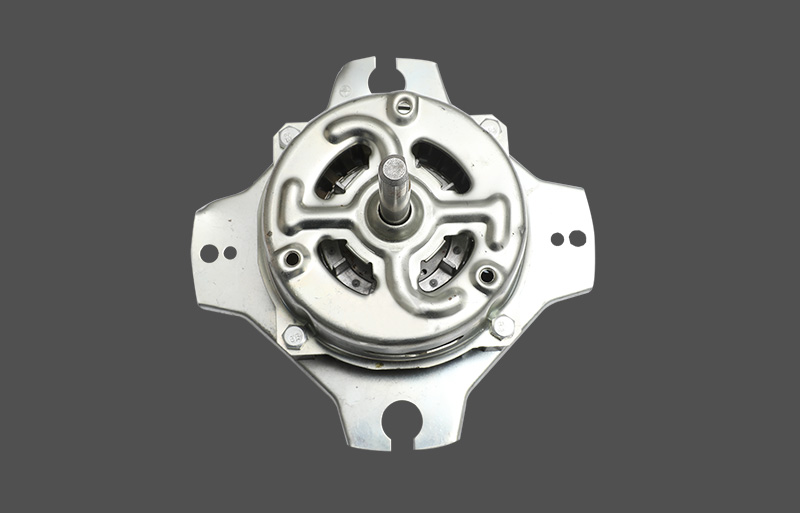

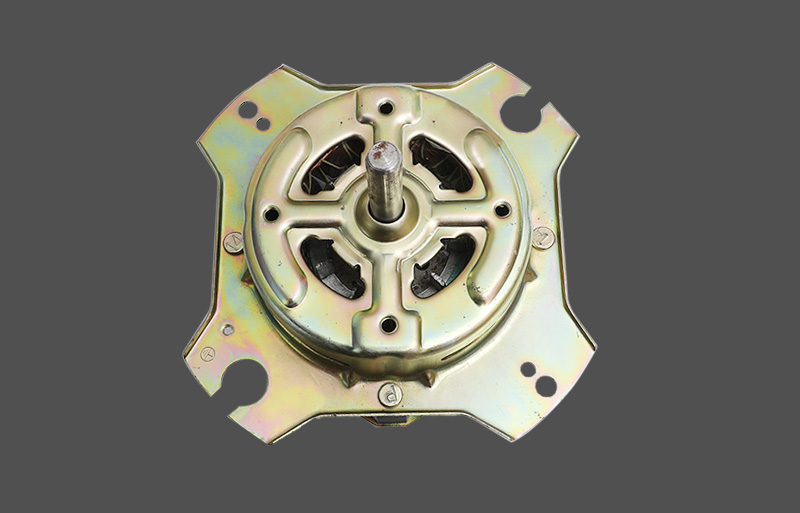

Optimize motor design

The design of the motor can be optimized for the specific needs of low-temperature environments. For example, choose materials that are more resistant to low temperatures to make key components of the motor, or optimize the heat dissipation structure of the motor to improve its low-temperature resistance. These design optimization measures will significantly enhance the reliability and stability of the motor in low-temperature environments and ensure its efficient operation for a long time.