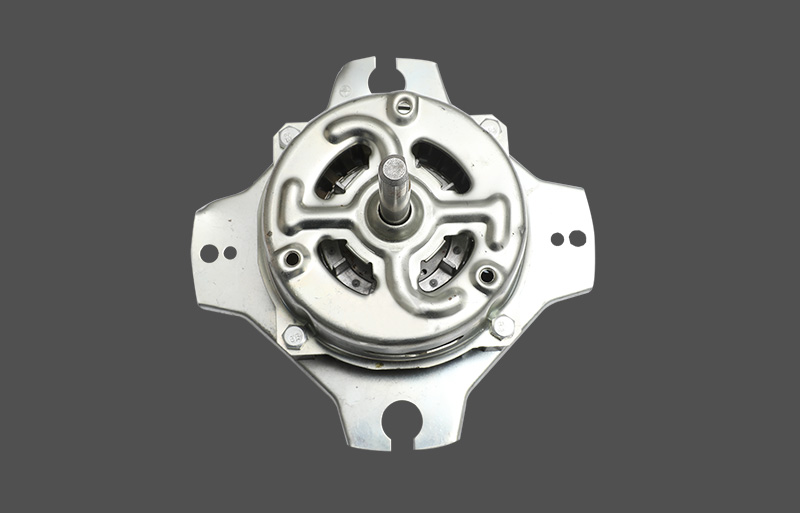

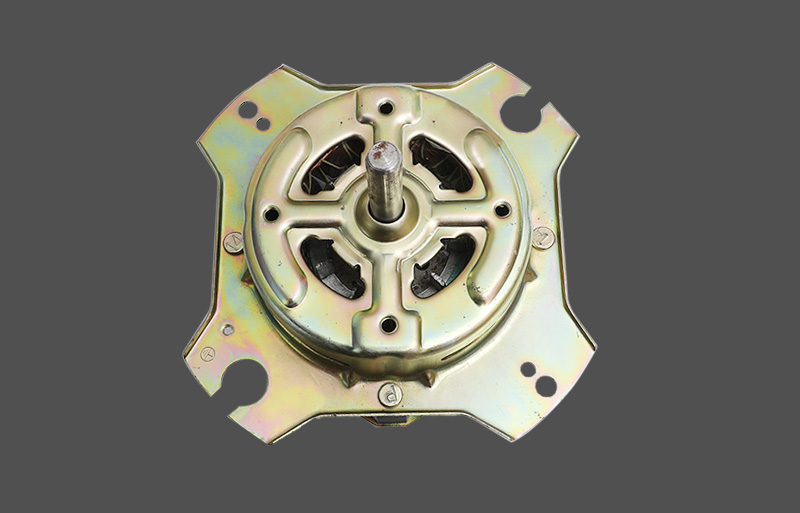

Washing machines are indispensable appliances in modern households. One of their core components, the motor, plays a key role in driving the normal operation of the washing machine. However, as the use cycle increases, the washing machine motor may encounter a variety of mechanical failures, which will not only significantly affect the performance of the washing machine, but also shorten its service life.

Analysis of common mechanical failures

The mechanical failures of washing machine motors can be mainly summarized into the following categories:

**Bearing wear**: The bearings of the motor are key components that support the rotating parts. After a long period of operation, the bearings may wear out, causing the motor to run unsteadily or even make abnormal noises.

**Rotor imbalance**: During the operation of the rotor, the rotor may be unbalanced due to uneven load distribution or manufacturing process defects. This situation will not only cause vibration and noise, but also affect the normal operation of the washing machine.

**Belt wear**: In some washing machine designs, the motor drives the washing tub through a belt. If the belt is worn, it will cause poor power transmission, thereby affecting the washing effect.

**Gear damage**: The gear system inside the motor may be damaged due to overload or material fatigue, which will cause the washing machine to fail to work properly.

**Improper installation**: If the motor is not properly aligned during installation, it may cause additional wear and noise during operation.

Solutions

For the above mechanical failures, here are some professional solutions:

Measures for bearing wear

- **Regular inspection**: The condition of the bearings should be evaluated regularly, especially when the washing machine is used frequently. By listening to abnormal noises or observing the operating status of the motor, the wear of the bearings can be effectively judged.

- **Replace the bearing**: Once the bearing is confirmed to be severely worn, it should be replaced in time. When replacing, the bearing should be selected in accordance with the original specifications to ensure its performance and durability.

- **Lubrication and maintenance**: After replacing the bearing, it is necessary to lubricate it regularly to reduce friction and extend its service life. Choose the right grease to avoid excessive or insufficient lubrication.

Measures for rotor imbalance

- **Dynamic balancing test**: With the help of professional dynamic balancing test equipment, the balance state of the rotor is detected. If imbalance is found, it can be corrected by adding balancing blocks or adjusting the load.

- **Regular maintenance**: During the use of the washing machine, the condition of the rotor needs to be checked regularly to ensure that it is not deformed or damaged to prevent vibration caused by rotor imbalance.

Measures for belt wear

- **Check belt condition**: Check belt wear regularly, including cracks, hardening or loosening. If belt is severely worn, replace it in time.

- **Adjust tension**: When replacing belt, make sure belt tension is moderate. A loose belt may cause poor power transmission, while a tight belt may increase the burden on the motor.

Measures for gear damage

- **Gear inspection**: Regularly check the gear system inside the motor to ensure that it is not worn or damaged. If gear damage is found, replace it in time.

- **Use appropriate materials**: When replacing gears, choose high-quality materials to ensure wear resistance and service life.